Anti-Foam Control Solutions-- Environmentally Friendly Foam Control Technologies

Anti-Foam Control Solutions-- Environmentally Friendly Foam Control Technologies

Blog Article

Discovering Various Kinds Of Anti-Foam Control Solutions for Various Industries

The administration of foam in commercial processes is an important aspect that can affect both item top quality and operational effectiveness across numerous industries. Different industries, such as food and drink, pharmaceuticals, and wastewater treatment, face distinct challenges connected to foam formation, demanding tailored anti-foam remedies. From silicone-based representatives to ecologically pleasant options, the option of appropriate control measures varies substantially. Comprehending these distinctions is essential for enhancing processes and guaranteeing conformity with sector criteria. What ramifications do these varying solutions have for environmental factors to consider and operational techniques?

Recognizing Foam Development

Foam development is an intricate physical phenomenon that happens when gas is trapped within a fluid, creating a secure structure of bubbles. This procedure is influenced by different aspects, consisting of the homes of the fluid, the nature of the gas, and outside conditions such as temperature level and stress (Anti-Foam Control Solutions). The stability of foam is mainly identified by the surface tension of the thickness and the liquid, as these properties dictate just how easily bubbles can linger and form

In lots of industrial applications, foam is an unwanted by-product that can hinder processes, reduce effectiveness, and effect item quality. The formation of foam is typically aggravated by frustration, blending, or chain reactions, resulting in enhanced operational challenges. Recognizing the devices behind foam formation is important for developing effective control approaches.

Types of Anti-Foam Agents

Numerous types of anti-foam agents are utilized across sectors to deal with the challenges positioned by foam development. These representatives can be broadly classified right into 2 main kinds: non-silicone-based and silicone-based anti-foam agents.

Silicone-based anti-foam agents are extremely effective due to their one-of-a-kind homes. They consist of polydimethylsiloxane (PDMS) and can considerably lower surface area tension, enabling for quick foam collapse. Their security at high temperature levels and in various pH atmospheres makes them appropriate for varied applications, consisting of production and chemical handling.

On the various other hand, non-silicone-based anti-foam agents include organic compounds such as fatty acids, esters, and waxes. They typically work by giving a physical obstacle that interrupts foam development.

In addition, some anti-foam representatives integrate both silicone and non-silicone parts to enhance performance throughout specific conditions. Comprehending the unique attributes and applications of these anti-foam representatives is important for picking the best remedy for foam control difficulties in various industrial settings.

Applications in Food and Drink

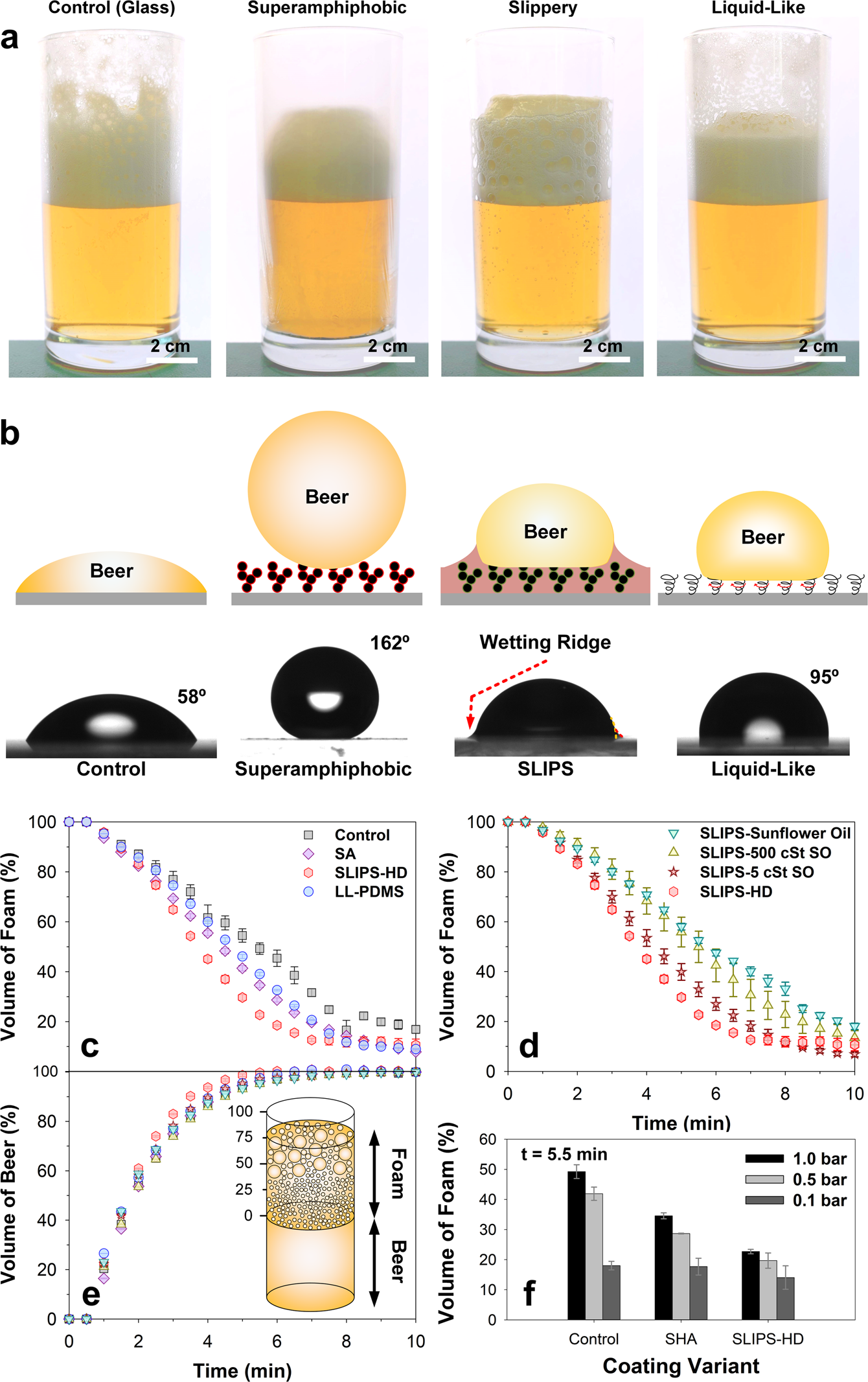

In the food and drink industry, efficient foam control is extremely important to making sure product top quality and procedure effectiveness. Too much foam can lead to operational difficulties, such as tools overflows, decreased processing capability, and variances in item appearance. Various applications within this sector, consisting of developing, dairy handling, and juice manufacturing, need customized anti-foam solutions to deal with particular lathering concerns.

As an example, in developing, foam stability is essential for both the quality look at more info of the beer and the effectiveness of the brewing procedure. Anti-foam agents are utilized to decrease unwanted foam throughout fermentation and product packaging, making certain a smoother operations and keeping preferred flavors. Likewise, in dairy products handling, the manufacturing of products like yogurt and cheese calls for careful foam management to avoid splilling and maintain texture.

In juice production, foam can obstruct filtering processes, impacting return and clearness. Here, the application of suitable anti-foaming representatives can maximize production rates and enhance item appearance - Anti-Foam Control Solutions. On the whole, choosing imp source the appropriate anti-foam control remedies customized to the special demands of each application is vital for preserving high quality and effectiveness in the food and beverage sector

Solutions for Pharmaceuticals

Reliable administration of foam generation is vital in the pharmaceutical industry, where accuracy and purity are critical. Foam can interfere with numerous procedures, including mixing, filtration, and sterilization, potentially jeopardizing product top quality and effectiveness. The selection of proper anti-foam services is necessary to keep operational performance and regulative compliance.

Silicone-based anti-foam representatives are extensively utilized as a result of their performance and compatibility with a series of pharmaceutical solutions. These agents work by reducing surface area tension, therefore destabilizing the foam framework. In addition, non-silicone alternatives, such as fatty acids and all-natural oils, are getting traction for their eco-friendliness and biodegradability, lining up with market patterns towards sustainable practices.

It is important to take into consideration the specific application when picking an anti-foam service, as the formulation has to not adversely impact the energetic ingredients or the final item. Additionally, compatibility with cleansing and sterilization processes is essential to make sure that the anti-foam representatives do not introduce contaminants. Constant surveillance and screening of foam control measures can improve efficiency, making certain that pharmaceutical processes stay optimum and compliant with rigorous market requirements.

Wastewater Treatment Methods

As markets increasingly concentrate on sustainability, carrying out efficient wastewater treatment strategies has actually come to be necessary for reducing environmental effects. Wastewater treatment is a crucial procedure that guarantees the risk-free disposal or reuse of commercial by-products, thus lessening contamination and conserving water sources.

One primary approach includes using biological therapy methods, such as turned on sludge processes, which make use of bacteria to damage down organic pollutants. This technique is typically complemented by advanced purification and sanitation techniques, making certain the effluent satisfies governing standards.

Furthermore, chemical therapy options, such as coagulation and flocculation, are utilized to remove suspended solids and liquified substances. The combination of anti-foam representatives is important in this context, as foam can prevent treatment performance and make complex phases of explanation and separation.

Additionally, membrane modern technologies, including reverse osmosis, are acquiring grip because of their capacity to produce high-grade effluent suitable for reuse in different applications. On the whole, a mix of these methods customized to specific sector demands can dramatically enhance the efficiency of wastewater therapy, adding to an extra sustainable future.

Final Thought

Efficient foam control is imperative across different markets to boost item quality and process efficiency. The choice of proper anti-foam representatives, whether environmentally friendly or silicone-based non-silicone alternatives, home plays a crucial role in resolving particular lathering difficulties experienced in food and beverage processing, pharmaceuticals, and wastewater treatment - Anti-Foam Control Solutions. Continued exploration of diverse anti-foam solutions will facilitate improved functional outcomes while guaranteeing environmental compliance and source recuperation, therefore adding to lasting methods within these markets

Different markets, such as food and beverage, pharmaceuticals, and wastewater treatment, face special difficulties associated to foam formation, necessitating customized anti-foam services. Various applications within this industry, including developing, dairy processing, and juice production, need customized anti-foam services to address specific frothing problems.

Anti-foam agents are used to minimize undesirable foam throughout fermentation and packaging, ensuring a smoother operations and keeping preferred tastes. These agents work by lowering surface tension, therefore destabilizing the foam framework. The choice of suitable anti-foam agents, whether environment-friendly or silicone-based non-silicone options, plays a crucial duty in attending to details frothing difficulties run into in food and beverage handling, pharmaceuticals, and wastewater treatment.

Report this page